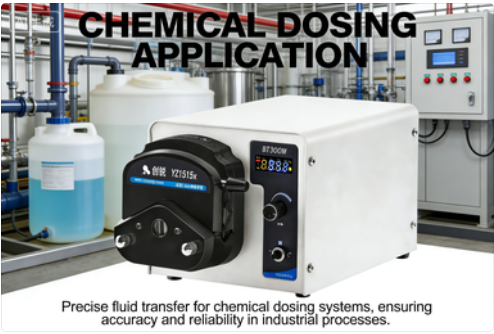

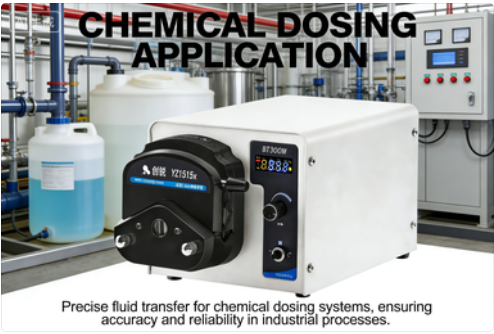

Chemical dosing errors can cost more than money. They can damage equipment, ruin batches, and create safety risks. Many engineers and purchasing managers face the same problem: how to move aggressive or sensitive fluids with control and reliability. This is where the peristaltic pump stands out.

In chemical processing, water treatment, food production, and many industrial systems, accuracy and safety matter every day. Choosing the wrong pump often leads to leaks, contamination, or high maintenance costs. In this article, we explain why this pump technology has become a trusted solution for chemical dosing and fluid transfer, and how it helps businesses run cleaner, safer, and more efficiently.

Additive dosing in industrial processes

2. Leak-Free Operation

Leaks are a serious risk in chemical plants. They cause safety hazards, corrosion, and environmental problems.

Because the fluid stays inside the tubing, there is no direct path for leaks. If the tube wears out, the fluid remains contained. This design greatly reduces spill risks and improves workplace safety.

For aggressive chemicals, this is one of the biggest reasons users switch to this solution.

3. Excellent Chemical Compatibility

Chemical compatibility is often a limiting factor for pumps. Many materials cannot handle strong acids or solvents.

Tubing materials such as silicone, EPDM, Viton, or PTFE-based compounds allow the pump to handle a wide range of chemicals. Users can select tubing based on chemical type, temperature, and pressure.

This flexibility makes it a strong peristaltic pump for chemicals across many industries.

4. Easy Maintenance and Lower Downtime

Maintenance costs often go unnoticed until failures happen.

Unlike pumps with seals and valves, this design has fewer wearing parts. In most cases, maintenance means replacing the tubing. This task takes minutes, not hours.

Lower maintenance brings clear benefits:

For factories running 24/7 operations, these advantages add real value.

Why It Works Well for Fluid Transfer

Chemical dosing is not the only task. Many systems also require safe and clean fluid movement between tanks or processes.

Gentle Handling of Fluids

Some chemicals degrade when exposed to shear or turbulence. The smooth pumping action protects fluid properties.

This is useful when transferring:

Polymers

Emulsions

Viscous chemicals

Sensitive additives

The pump moves fluid without crushing or mixing it aggressively.

Ability to Run Dry

Many pump types fail if they run without liquid. This design can operate dry without damage.

In real-world conditions, this protects equipment during startup, shutdown, or unexpected supply interruptions. For users handling expensive or dangerous chemicals, this adds an extra safety layer.

Self-Priming Performance

Self-priming capability allows the pump to lift fluid from a lower level without manual priming.

This feature is valuable in:

Drum unloading systems

Tank-to-tank transfer

Mobile dosing units

It also simplifies system design and installation.

Industrial Applications That Benefit Most

Water and Wastewater Treatment

Municipal and industrial water systems rely on stable chemical dosing. Chlorine, coagulants, and pH adjusters require accurate injection.

Many plants use an industrial peristaltic pump to ensure reliable operation and reduce maintenance work in harsh environments.

Chemical Manufacturing

In chemical production, contamination can ruin entire batches. The isolated fluid path helps maintain product purity.

These pumps also handle viscous or abrasive fluids better than many alternatives.

Food and Beverage Processing

Hygiene standards are strict in this industry. Easy-to-clean tubing and gentle fluid handling make this technology suitable for additives, flavoring, and cleaning chemicals.

Mining and Flue Gas Treatment

Slurries and abrasive chemicals often damage conventional pumps. The tubing-based design tolerates solids better and protects mechanical parts.

Comparing with Other Pump Types

Versus Diaphragm Pumps

Diaphragm pumps also offer chemical resistance, but they rely on valves and membranes. These parts can clog or fail.

This alternative provides smoother flow and simpler maintenance, especially at low flow rates.

Versus Gear or Centrifugal Pumps

Gear and centrifugal pumps struggle with aggressive chemicals and low-flow precision. Seal leakage is a common issue.

For dosing and controlled transfer, tubing-based pumping often delivers better long-term performance.

How to Choose the Right Model

Selecting the correct pump requires understanding your process needs.

Key factors include:

Tubing selection is just as important as pump size. Choosing the right material extends service life and improves reliability.

Working with an experienced peristaltic pump manufacturer can help avoid costly mistakes.

OEM and Customization Benefits

Many equipment builders require pumps that integrate smoothly into their systems. An OEM peristaltic pump solution offers flexibility in design, control, and branding.

Customization options may include:

Motor type and voltage

Pump head design

Control interfaces

Mounting structures

This allows system builders to optimize performance while keeping costs under control.

Cost Efficiency Over Time

Initial purchase price is only part of the equation. Long-term costs matter more.

Over time, users often see savings from:

When viewed across the equipment lifespan, this pump type often delivers strong return on investment.

Quality Standards and Compliance

In regulated industries, compliance matters. Many models meet international standards for safety and performance.

When sourcing from a reliable supplier, users can request documentation, testing data, and quality certifications to support their projects.

Why Partner with a Professional Manufacturer

Choosing the right supplier is as important as choosing the right pump.

A professional factory offers:

As a China-based manufacturer specializing in peristaltic pump products, our main business focuses on industrial, chemical dosing, and fluid transfer solutions. We support distributors, equipment builders, and end users with reliable products and technical guidance.

Whether you need a standard chemical dosing pump or a custom-built solution for your system, working directly with a factory helps reduce costs and improve response time.

Final Thoughts

Chemical dosing and fluid transfer demand precision, safety, and reliability. This pump technology solves many common problems found in traditional pump systems.

From leak-free operation to easy maintenance and strong chemical resistance, it has become a trusted solution across many industries. When chosen and applied correctly, it helps protect processes, people, and profits.

If you are planning a new project or upgrading an existing system, understanding how this solution fits your application is the first step toward better performance.