Introduction: Peristaltic pumps are only transmitted through hoses to ensure the sterility and cleanliness of medical treatment. Conventional consumables can be used once.

"Peristaltic pumps are only transmitted through hoses to meet the sterility and cleanliness requirements of medical treatment. As consumables, hoses can be used once, with precise flow control and safe use, making them the core components of modern endoscope flushing systems. This article will explore its unique advantages, working principles, key selection considerations and future development trends in endoscope applications, and provide professional guidance for medical equipment engineers and purchasers to optimize flushing solutions."

1. The role of peristaltic pumps in endoscope flushing

By steadily delivering saline and disinfectant, blood, mucus or tissue residues in front of the endoscope lens are removed.

Precisely control the flow rate (50-500 ml/min) to avoid excessive pressure from damaging the mucosa.

1.2 Auxiliary biopsy and treatment

Suction function: Remove liquid or microtissue samples with negative pressure (-0.2 to -0.8 bar).

Drug delivery: precise injection of dyes (such as Lugol's iodine) or hemostatic drugs (such as epinephrine).

1.3 Reduce the risk of infection

Valveless structure: Reduce the risk of bacterial growth and comply with ISO 13485 medical device standards.

2. Working principle and advantages of peristaltic pumps

2.1 Working principle

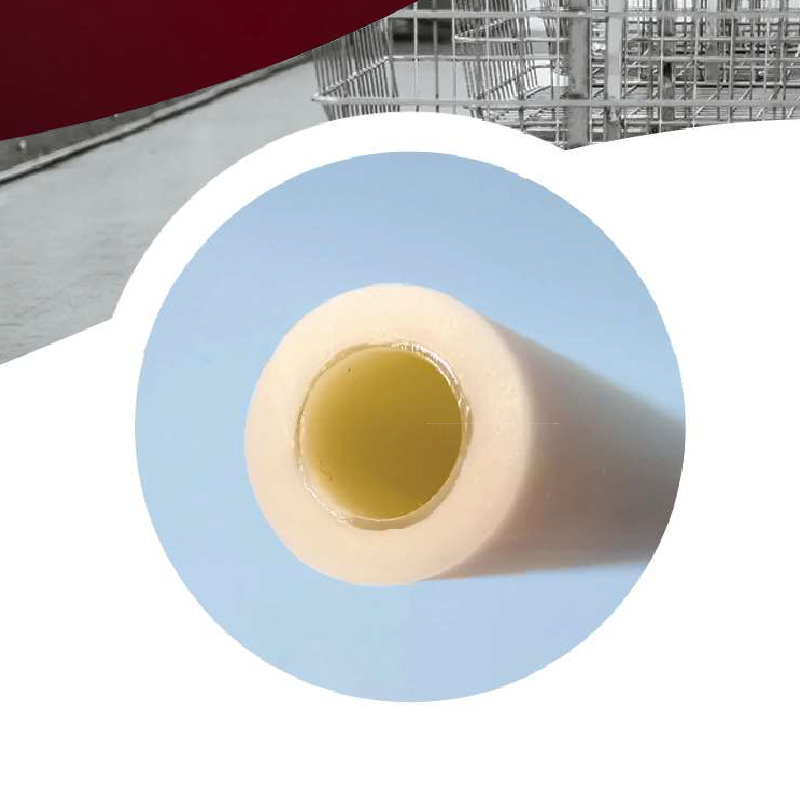

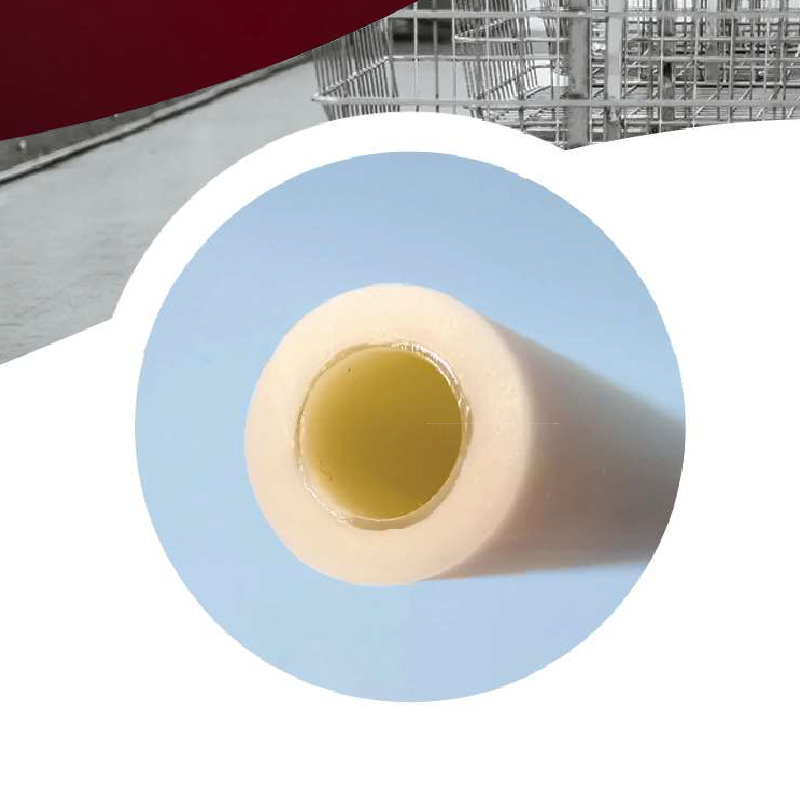

The peristaltic pump squeezes the hose through the rotating roller to form negative pressure, sucks in the liquid and discharges it positively to achieve pollution-free delivery.

2.2 Core advantages

Feature description

Sterile: Only the pump tube contacts the liquid and is disposable

Low shear force, suitable for delivering liquids containing cells or particles

Easy maintenance, quick replacement of pump tubes, no need for complex disinfection

3. Key points for selecting endoscopic peristaltic pumps

3.1 Flow and pressure requirements

Conventional endoscopic examination: 50 – 300 ml/min (such as gastrointestinal endoscopy and cystoscopy).

High flow requirements: 300 – 600 ml/min (such as arthroscopic flushing).

3.2 Pump tube material selection

Highly elastic medical silicone, compatible with saline and alcohol

TPE (thermoplastic elastomer) is chemically resistant and suitable for long-term use

Pharmed® Ultra clean, suitable for high-precision drug delivery

4. Practical application cases of peristaltic pumps in endoscopy

4.1 Gastrointestinal endoscopy

Problem: Gastric juice and blood affect the clarity of vision.

Solution: The peristaltic pump continuously flushes at a flow rate of 200 ml/min, combined with rapid suction cleaning.

Demand: High-flow flushing (400 ml/min) to remove debris.

Solution: Choose a high-pressure peristaltic pump .

5. Future development trends

Intelligent control: AI algorithm automatically adjusts the flushing flow according to the endoscopic image.

Miniature design: Suitable for capsule endoscopy (diameter <5 mm).

Energy saving and low noise: Optimize motor drive technology to improve the operating room experience.

Conclusion:

Peristaltic pumps have become an ideal choice for endoscope flushing systems due to their sterility, precise flow control, and easy maintenance. Medical device manufacturers should focus on flow matching, pump tube materials, and intelligent upgrades to optimize the effects of endoscopic surgery.