Choosing the right peristaltic pump manufacturer in China can feel overwhelming. There are many factories, many prices, and many promises. Yet one wrong decision can lead to unstable flow, short tube life, or long delivery delays.

This guide helps you make a smart choice. It explains what really matters when buying a peristaltic pump from China, how to judge suppliers, and how to balance quality with cost. If you source pumps for industrial use, dosing systems, or high-flow applications, this article is for you.

Why Global Buyers Source Peristaltic Pumps from China

China is one of the world’s largest manufacturing centers for fluid handling equipment. Many global brands already rely on Chinese factories for OEM and ODM production.

Here are the main reasons buyers look to China:

Cost advantage: Manufacturing and supply chain costs are lower

Wide product range: From small dosing units to high flow models

Flexible customization: Tubing, motors, voltage, and control options

Growing technical level: Many factories now meet CE, RoHS, and ISO standards

For buyers who understand how to choose, sourcing from China can reduce total costs by 20–40% compared to local suppliers.

What Is a Peristaltic Pump and Why It’s Widely Used

A peristaltic pump moves fluid by compressing a flexible tube or hose. Rollers or shoes push the fluid forward as they rotate. The fluid never touches the pump body.

This simple design brings key benefits:

Because of this, peristaltic pumps are widely used in:

Water and wastewater treatment

Chemical dosing systems

Food and beverage processing

Mining and slurry transfer

Pharmaceutical production

Industrial users value reliability and low downtime. That’s why this pump type continues to grow in demand.

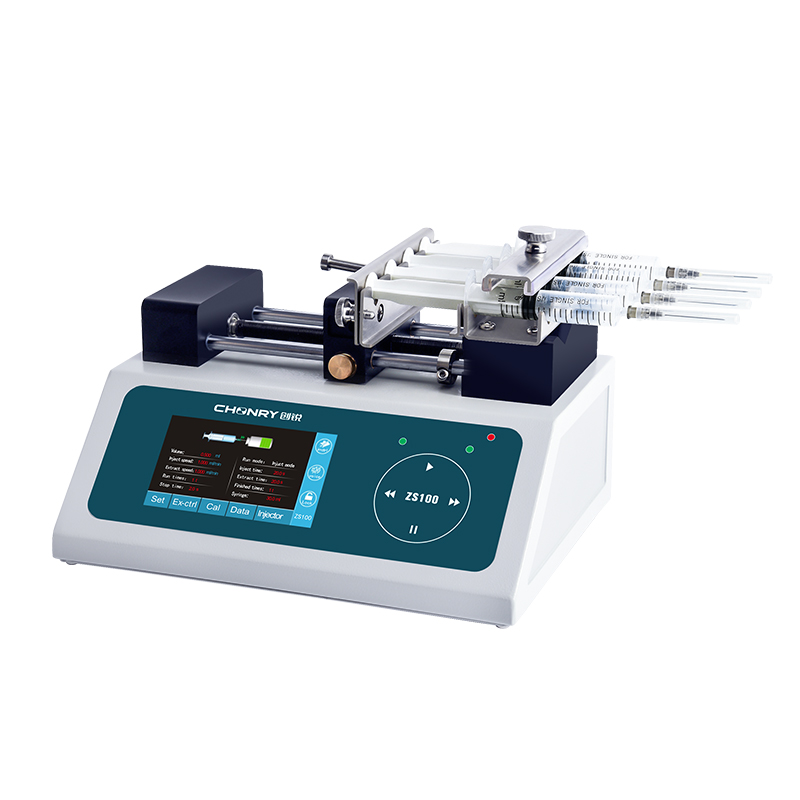

Types of Peristaltic Pumps Offered by Chinese Manufacturers

Before choosing a supplier, you need to understand the product categories they offer. A strong manufacturer should cover multiple use cases.

Industrial Peristaltic Pump

Industrial models handle harsh conditions. They work with abrasive, viscous, or corrosive fluids. Many support continuous operation for 24/7 production lines.

Key features often include:

These pumps are common in mining, chemical plants, and environmental engineering.

Dosing pumps focus on precision rather than volume. They are used when exact amounts matter.

Typical applications include:

Chemical dosing in water treatment

Nutrient dosing in agriculture

Additive control in food processing

High-quality dosing pumps can reach accuracy levels of ±1% or better. Speed control and stable tubing quality are critical here.

Peristaltic Metering Pump

Metering pumps take precision further. They often integrate with PLC systems or automated lines.

Common features include:

Buyers should confirm calibration methods and long-term stability when selecting this type.

High Flow Peristaltic Pump

High flow models are designed for bulk transfer. They handle thick slurry, mud, or solid-laden fluids.

Important design points:

Large-diameter hoses

Strong compression force

High-torque motors

These pumps are widely used in mining, ceramics, and construction industries.

Key Factors to Evaluate a Peristaltic Pump Manufacturer in China

Not all factories are equal. Some focus on trading, others on real manufacturing. Below are the most important factors to check.

Manufacturing Experience and Focus

Ask how long the factory has specialized in peristaltic pumps. A factory with 10+ years of focus usually has better process control and tube formulations.

Check whether they:

Experience reduces risk.

Product Quality and Certifications

Reliable manufacturers follow international standards.

Look for:

ISO 9001 quality management

CE compliance for export markets

RoHS compliance for materials

Ask for test reports. A serious factory can provide pressure tests, life cycle tests, and flow accuracy data.

Tube and Hose Materials

The tube is the heart of the pump. Tube quality directly affects flow stability and service life.

Common materials include:

Silicone

Norprene

Viton

EPDM

NBR

Ask about tube lifespan under real working conditions. For industrial use, tube life can range from 500 to over 3,000 hours, depending on material and speed.

Customization Ability

Many buyers need non-standard solutions.

Good manufacturers can customize:

Voltage and frequency

Flow range

Control interfaces

Pump head configuration

Branding and packaging

Customization shows technical strength, not just assembly capability.

Lead Time and Production Capacity

Fast response matters, especially for project-based buyers.

Ask about:

Stable factories often deliver standard pumps within 7–15 days.

Understanding Peristaltic Pump Price in China

Price is important, but it should not be the only factor.

Several elements affect cost:

Pump size and flow rate

Motor type and brand

Control system complexity

Tube material and diameter

Certification requirements

For reference:

Small dosing units may start at USD 100–300

Industrial models often range from USD 500–2,000+

High flow systems can exceed USD 3,000, depending on configuration

Very low prices often mean compromises in tube life or motor quality.

Common Mistakes Buyers Make When Choosing a Supplier

Avoid these common issues:

Choosing the cheapest quote without testing

Ignoring after-sales support

Not checking real factory photos or audits

Overlooking tube replacement cost

A slightly higher upfront cost often saves money over the pump’s lifetime.

How to Verify a Real Peristaltic Pump Factory

Here are simple ways to verify legitimacy:

Request a factory video tour

Ask for production line photos

Check export history

Ask technical questions and judge response depth

Real manufacturers answer clearly. Traders often avoid details.

Why Long-Term Cooperation Matters

A peristaltic pump is not a one-time product. Tubes need replacement. Systems may expand. Standards may change.

Working with a stable manufacturer helps you:

Maintain consistent quality

Reduce communication time

Improve future pricing

Get faster technical support

Many global buyers build partnerships, not just orders.

How the Right Manufacturer Helps Your Business

A reliable peristaltic pump supplier does more than ship products.

They help you:

This support directly impacts your project success and customer satisfaction.

Final Thoughts and Next Step

Choosing a peristaltic pump manufacturer in China is about balance. You want stable quality, fair pricing, and long-term support. When chosen correctly, a Chinese factory can be a strong partner for industrial pumping solutions.

Our main business focuses on manufacturing peristaltic pump solutions for industrial transfer, dosing, metering, and high-flow applications. We support OEM customization, stable supply, and global delivery.

If you are planning a project or comparing options, now is the right time to talk.

Reach out to discuss your application, flow requirements, and working conditions. The right pump choice today can save you years of trouble tomorrow.