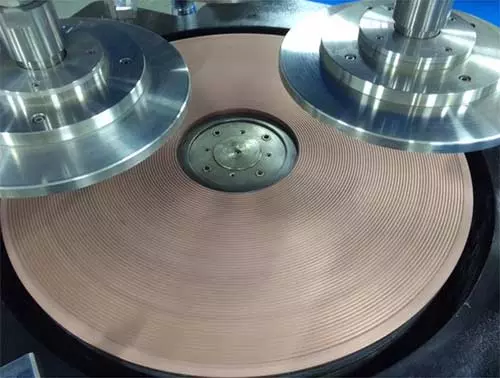

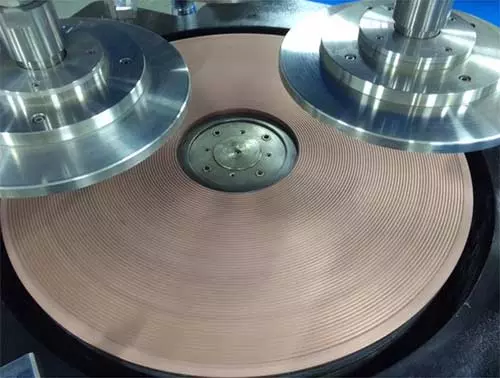

What Is the Sapphire Grinding Polishing Fluid?

A sapphire substrate includes a generally planar surface having a crystallographic orientation selected from the group consisting of a-plane, r-plane, m-plane, and c-plane orientations, and having a nTTV of not greater than about 0.037 μm/cm2, wherein nTTV is total thickness variation normalized for surface area of the generally planar surface, the substrate having a diameter not less than about 9.0 cm.

The main ingredients in sapphire polishing fluid are: abrasives, pH regulators, surfactants, chelating agents, etc. Among them, abrasives are one of the most important factors affecting the CMP polishing effect, and they mainly affect the mechanical action in chemical mechanical polishing. Currently, commonly used abrasives mainly include single abrasives such as diamond, alumina, and silicon oxide, as well as silicon oxide/alumina mixed abrasives and core-shell composite abrasives.

What Is the Main Role of Sapphire Grinding Polishing Fluid?

Sapphire grinding polishing fluid is designed to meet various polishing specification requirements in substrate manufacturing processes such as C-side, A-side, and R-side of sapphire wafers, from leveling and grinding to CMP processing. Optimized solutions support different tool sets and process conditions to achieve high removal rates without subsurface damage while providing excellent stability.

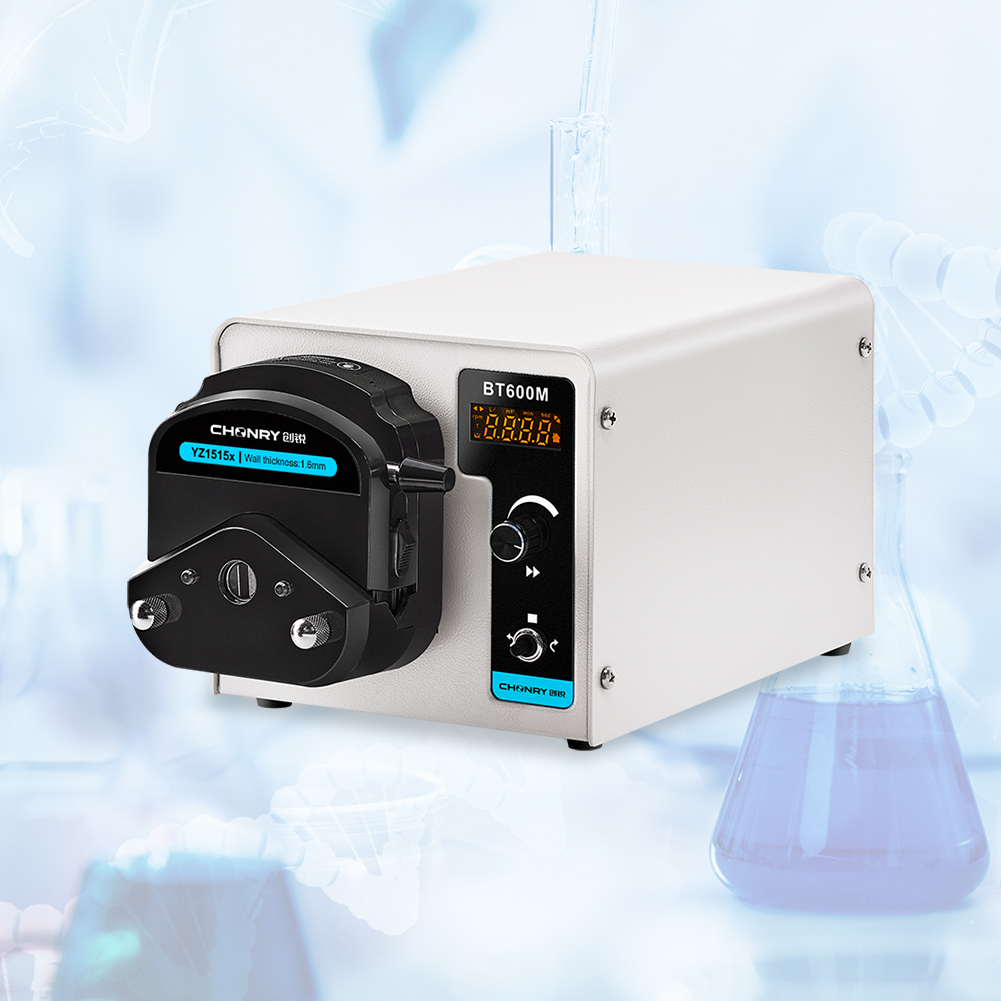

How to Transfer the Sapphire Grinding Polishing Fluid?

Peristaltic pumps can deliver most polishing fluids. The special structure of the peristaltic pump strictly separates the pump liquid from the pump body. The tube and peristaltic pump head can be completely separated. The pump tube can be replaced at any time. The peristaltic pump has obvious advantages in the chemical polishing process.

(1) No pollution

During the chemical polishing process, the polishing fluid delivered by the peristaltic pump always flows in the pump tube and does not contact the pump body, especially the mechanical transmission mechanism. This avoids metal contamination during the chemical mechanical polishing process and does not cause damage due to the polishing fluid. Corrosive and damage the mechanical parts of the pump body.

(2)Self-priming ability

The peristaltic pump can generate sufficient vacuum suction to suck the polishing fluid from the pool into the pump tube when working, thus eliminating the process of pre-filling the pump and suction tube, and also eliminating the need for submerged filling, so the pump no longer needs to be placed below the liquid source level, the pump is more flexible in its installation location and better integrated with the polisher itself.

(3) Simple operation

Peristaltic pump operation is straightforward. The installation, disassembly and locking of the peristaltic pump tubing can be requested at any time. The control is simple. Speed control can be achieved through the speed control knob or operation panel. In addition, according to different flow requirements, 2 or 3 pump heads can be connected in series to the peristaltic pump at the same time, realizing a multi-channel supply of polishing fluid.

Recommend M series Peristaltic Pump Liquid Constant Transfer